What's New

Inspecting and Cleaning Reusable Respirators

March 28, 2022

The proper cleaning and maintenance of respirators is an important area that is commonly overlooked. All respiratory protection equipment needs to be in good condition to work effectively and to be able to supply the level of protection expected by the user.

Inspection

Inspect facepiece, filters and/or cartridges prior to use. Any damaged or defective parts must be replaced prior to use. In addition:

- Ensure face seal and cartridge/filter connection seal area are not distorted

- Make sure straps are intact and have good elasticity

- Ensure inhalation/exhalation valves lay flat against valve seat

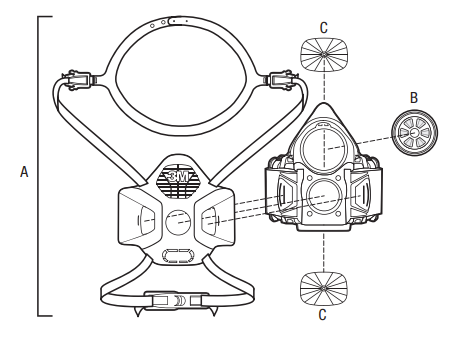

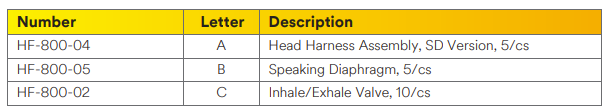

- Ensure speaking diaphragm (SD) seal is in place, the SD film is intact, and the SD is securely inserted in the facepiece

- Ensure filters/cartridges are securely attached to facepiece prior to use and the cartridge/filter release button is in the latched position

Cleaning

Cleaning is recommended after each use.

- Remove filters and/or cartridges

- Remove additional facepiece components for cleaning, as needed

- Clean facepiece with a 3M™ Respirator Cleaning Wipe, 504 (as an interim cleaning method) or by immersing in warm cleaning solution, up to 49ºC (120ºF), and scrub with soft brush or cloth until clean– add neutral detergent if necessary

- Ensure the cartridge/filter connection area is free of debris. Use a cloth or soft brush to reach this area and/or move facepiece back and forth quickly while it is immersed in cleaning solution

- Rinse in fresh, warm water

- Air dry in a non-contaminated atmosphere You can also use a respirator washer to clean the facepiece.

- Water temperature should not exceed 49ºC (120ºF)

- Air dry in a non-contaminated atmosphere